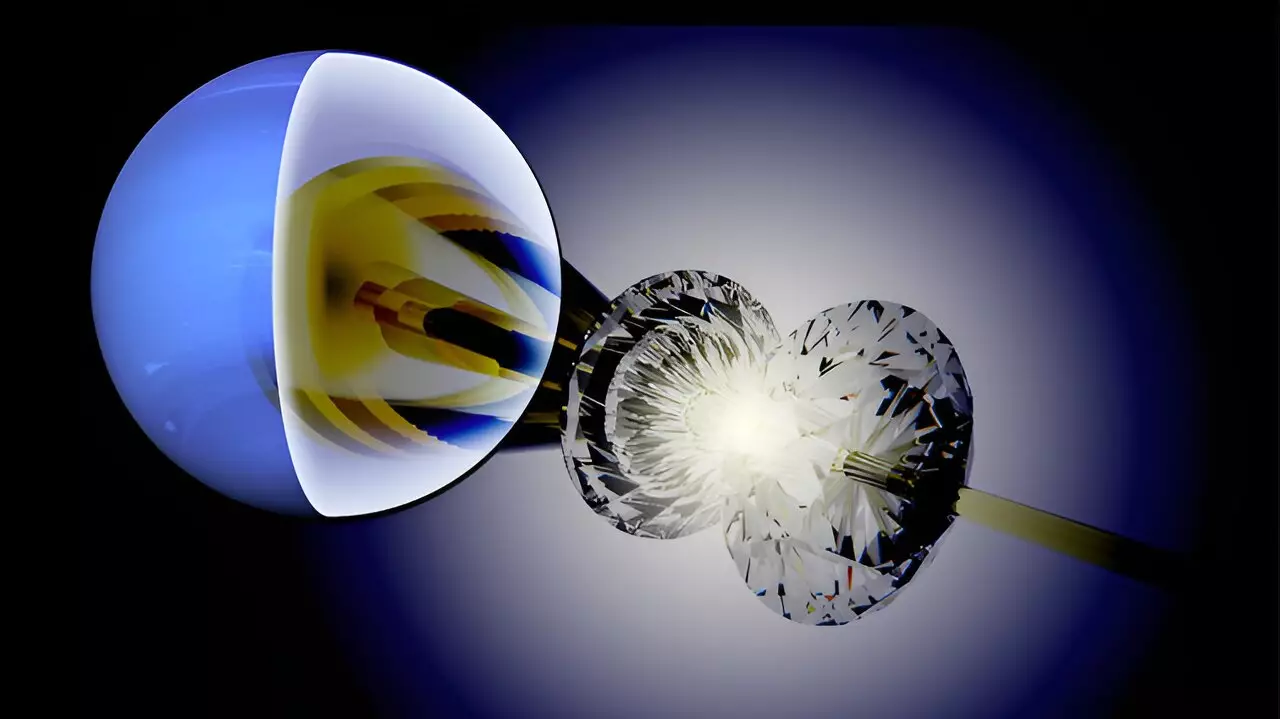

In a recent publication in the Journal of Applied Physics, a team of researchers from Lawrence Livermore National Laboratory, Argonne National Laboratory, and Deutsches Elektronen-Synchrotron introduced a new sample configuration that significantly enhances the reliability of equation of state measurements in high-pressure experiments. This breakthrough allows for the attainment of pressure conditions previously unattainable in diamond anvil cells.

The development of the toroidal diamond anvil cell by LLNL has been instrumental in pushing the static pressure limits in condensed matter sciences. However, advancing the sample fabrication process was identified as a crucial next step in conducting more complex experiments. Static compression experiments at pressures exceeding 300 GPa present significant challenges, including less than ideal compression environments. The newly introduced sample package addresses this challenge, providing an improved compression environment that enhances the quality of equation of state data.

The implementation of the toroidal diamond anvil cell, with its ability to surpass 300 GPa, along with the microfabrication of sample packages, represents a major advancement in static compression experiments at multi-megabar conditions. The data obtained from these experiments further complements the information gathered from gas-gun and NIF experiments conducted at LLNL. This innovation enables the calibration of equation-of-state measurements for materials at pressures more than double that of previous diamond anvil-cell-derived equations of state.

To create the sample package, researchers utilized a 10-step microfabrication process within the small sample chamber of the toroidal diamond anvil cell. The process involved embedding the target material in a uniform capsule made of soft metal, which serves as a pressure-transmitting medium. This capsule ensures the uniform redistribution of stress around the sample material during compression, resulting in reliable equation-of-state measurements even on a micron scale.

The experiments to test the sample package methodology were conducted at Argonne National Laboratory Sector 16 HPCAT and Deutsches Elektronen-Synchrotron PETRA-III. The researchers selected molybdenum as the target material and used a copper pressure-transmitting medium. The success of this methodology with molybdenum indicates the broad applicability of this sample package approach in high-pressure experiments across various fields.

Lead author Claire Zurkowski expressed optimism about the future of sample-package microfabrication in the toroidal diamond anvil cell. The innovative sample-encapsulation method is expected to push static equation-of-state calibrations in physics, chemistry, and planetary science materials into the multi-megabar pressure range. This advancement addresses the current lack of static compression data at such extreme pressure conditions and opens up new possibilities for research in high-pressure experiments.

The development of the sample package represents a significant advancement in high-pressure experiments, enabling researchers to conduct reliable equation-of-state measurements at unprecedented pressure conditions. This innovation has the potential to revolutionize the field of static compression experiments and contribute valuable data to various scientific disciplines.

Leave a Reply