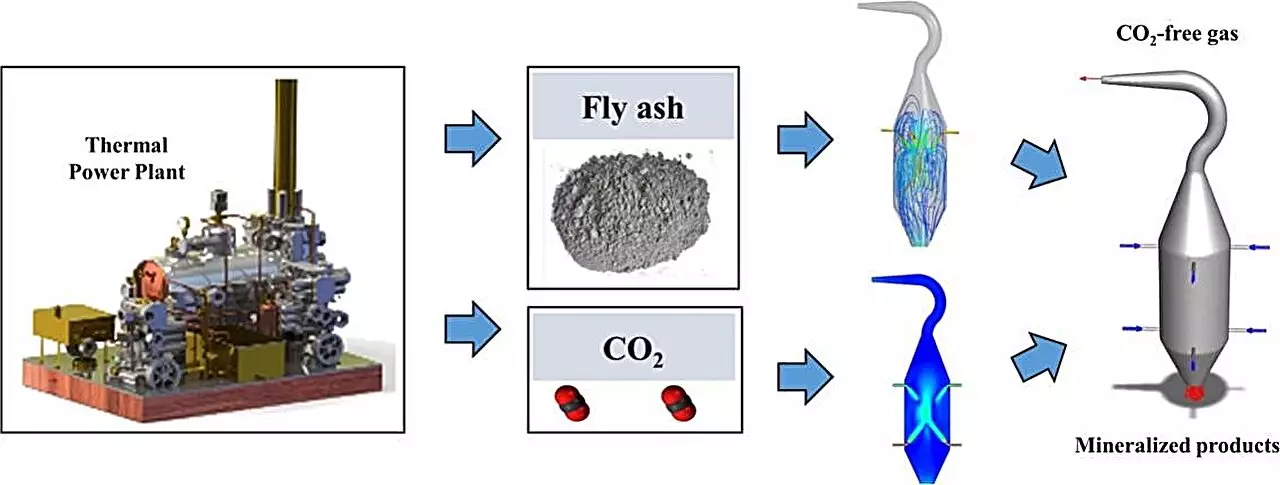

In the realm of sustainable waste management and CO2 sequestration, researchers have made significant strides in developing reactors that can effectively mineralize carbon dioxide using fly ash particles. This innovative technique holds the promise of providing a long-term and eco-friendly solution to the critical issue of greenhouse gas emissions, all while repurposing an industrial by-product.

The rise of industrialization has led to a sharp increase in CO2 emissions, a major contributor to global warming. While current carbon capture, utilization, and storage (CCUS) technologies exist, they face challenges related to efficiency and cost. Fly ash, a by-product of coal combustion, presents a promising opportunity for CO2 mineralization, transforming waste into a valuable resource and helping to reduce emissions.

However, existing reactor designs have struggled to achieve the desired balance between gas-particle interactions and operational effectiveness. This highlights the urgent need for a thorough examination of innovative reactor configurations and operational enhancements. A recent study conducted by Shanghai Jiao Tong University and published in the Energy Storage and Saving journal on May 7, 2024, delves deep into this topic.

The research introduces two distinct reactor designs optimized for CO2 mineralization using fly ash, with computational fluid dynamics playing a key role in their development. The impinging-type inlet design is notable for its ability to enhance interfacial interactions, prolonging particle residence time and significantly increasing mineralization rates. On the other hand, the quadrilateral rotary-style inlet design emphasizes a streamlined flow for better mixing and reaction efficiency.

Through a comprehensive exploration of operational parameters such as flue gas velocity, carrier gas velocity, and particle velocity, the study identified optimal ranges that are poised to elevate reactor performance to new heights. These parameters ensure efficient CO2 mineralization and effective phase separation post-reaction, paving the way for more sustainable waste management practices.

Dr. Liwei Wang, the lead researcher on the study, emphasized the significance of these findings, stating that the refined reactor designs and operational parameters have led to a significant improvement in CO2 mineralization efficiency. This breakthrough not only benefits sustainable waste management practices but also offers a practical approach to reducing industrial carbon emissions in alignment with global climate initiatives.

The implications of this research extend beyond the laboratory, particularly for coal-fired power plants. By utilizing fly ash for CO2 mineralization, this study presents a transformative opportunity to decrease carbon emissions and alleviate the environmental impact of fly ash disposal. This innovative approach offers a holistic solution to waste management and CO2 sequestration, potentially reshaping the landscape of CCUS technology.

The ongoing research in sustainable waste management and CO2 sequestration is pushing the boundaries of innovation and paving the way for a more environmentally friendly future. By focusing on novel reactor designs, optimized operational parameters, and transformative applications, researchers are demonstrating a commitment to addressing the challenges of industrialization and climate change head-on.

Leave a Reply