In the world of manufacturing, ensuring that components are free of defects is crucial to maintaining quality standards. Additive manufacturing, also known as 3D printing, has introduced a new set of challenges when it comes to detecting defects. The University of Illinois Urbana-Champaign has recently developed a groundbreaking method that utilizes deep machine learning to identify defects in additively manufactured components.

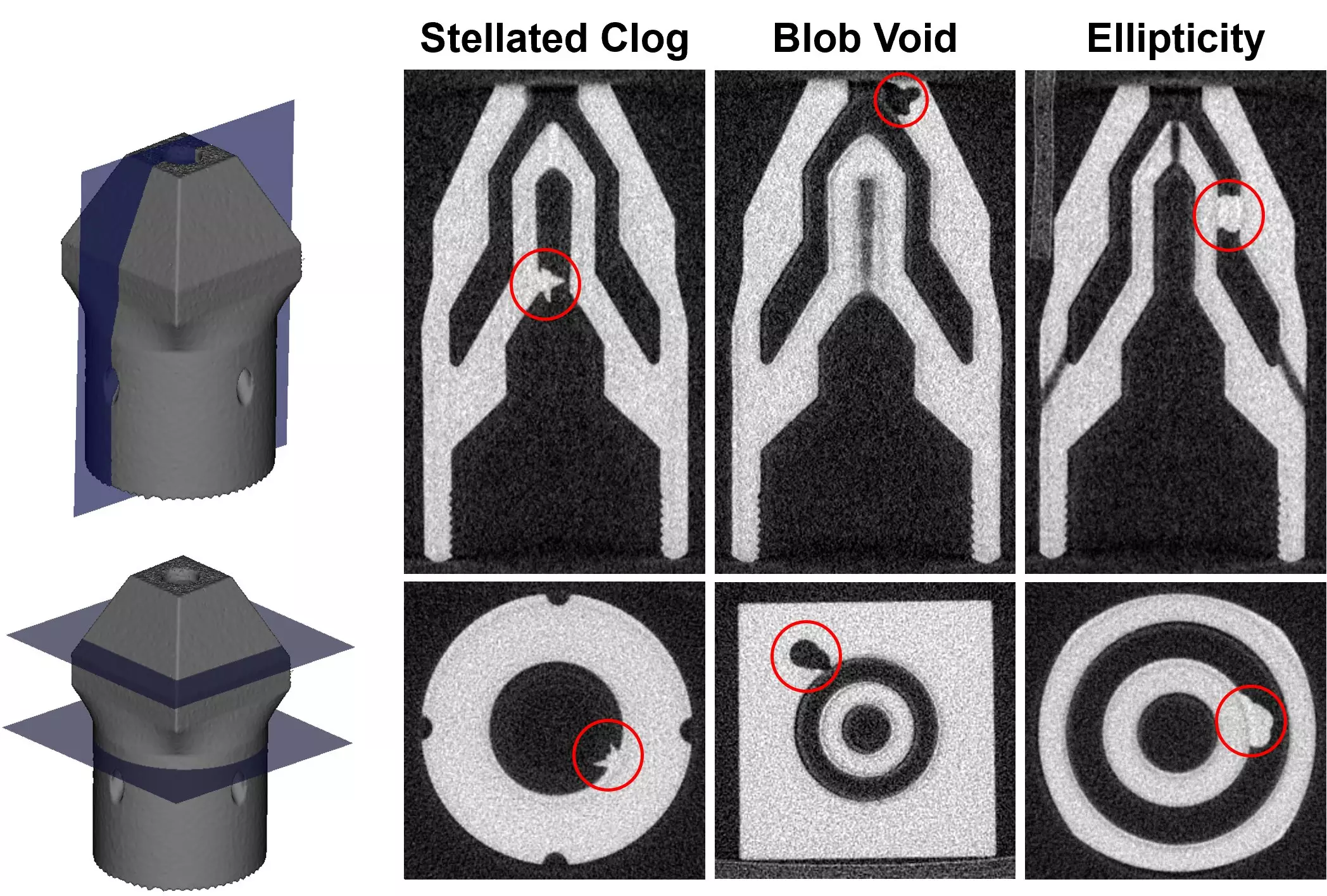

Researchers at the university employed computer simulations to create thousands of synthetic defects, each with varying sizes, shapes, and locations. This extensive dataset allowed their deep learning model to be trained on a wide range of possible defects, enabling it to differentiate between defective and defect-free components. The algorithm was then tested on physical parts, successfully identifying numerous defects that had not been previously seen by the model.

Professor William King, the project leader, emphasized the significance of this technology in addressing a major challenge in additive manufacturing. By utilizing computer simulations and deep learning, the researchers were able to develop a highly accurate defect detection system. This advancement is particularly crucial in scenarios where important features of components are hidden from view, making traditional inspection methods ineffective.

The Research

The research, published in the Journal of Intelligent Manufacturing, detailed the innovative approach of detecting and classifying hidden defects in additively manufactured parts. X-ray computed tomography was used to inspect the internal features and defects of 3D components that were not readily visible. The collaboration of experts from various institutions, including the University of Illinois Urbana-Champaign, University of Maryland, University of Michigan, and Zhejiang University, highlights the interdisciplinary nature of this research.

The development of a defect detection method using deep learning and X-ray computed tomography represents a significant advancement in the field of additive manufacturing. By leveraging computer simulations and cutting-edge technology, researchers have successfully addressed a critical issue in the industry. This breakthrough has the potential to enhance the quality control processes of additive manufacturing and pave the way for further innovations in defect detection techniques.

Leave a Reply