Boston Dynamics, a company renowned for its cutting-edge robotics, is setting the stage for a remarkable transformation in the manufacturing industry with its all-electric humanoid robot, Atlas. This innovation, which has evolved from its hydraulic predecessors, is poised to work in tandem with human operators at a Hyundai factory later this year. This marks a significant milestone in the application of humanoid robots, moving from conceptual demonstrations to real-world industrial uses. This transition is not merely about replacing human labor; it is about enhancing it. The key lie in the robot’s capability to handle tasks that are either physically demanding or inherently awkward for human workers.

The Unique Role of Atlas

Kerri Neelon, a spokesperson for Boston Dynamics, elaborates on the unique strengths of the Atlas robot. With the ability to lift heavy loads and navigate tight spaces, the Atlas is engineered to complement human workers in the manufacturing sector rather than supplant them. This aligns with a broader vision where humanoid robots serve as multipurpose assistants, capable of adapting to various tasks much like their human counterparts. Such capabilities raise intriguing possibilities for operational efficiency and safety in work environments, suggesting a future where humans and robots form collaborative teams for enhanced productivity.

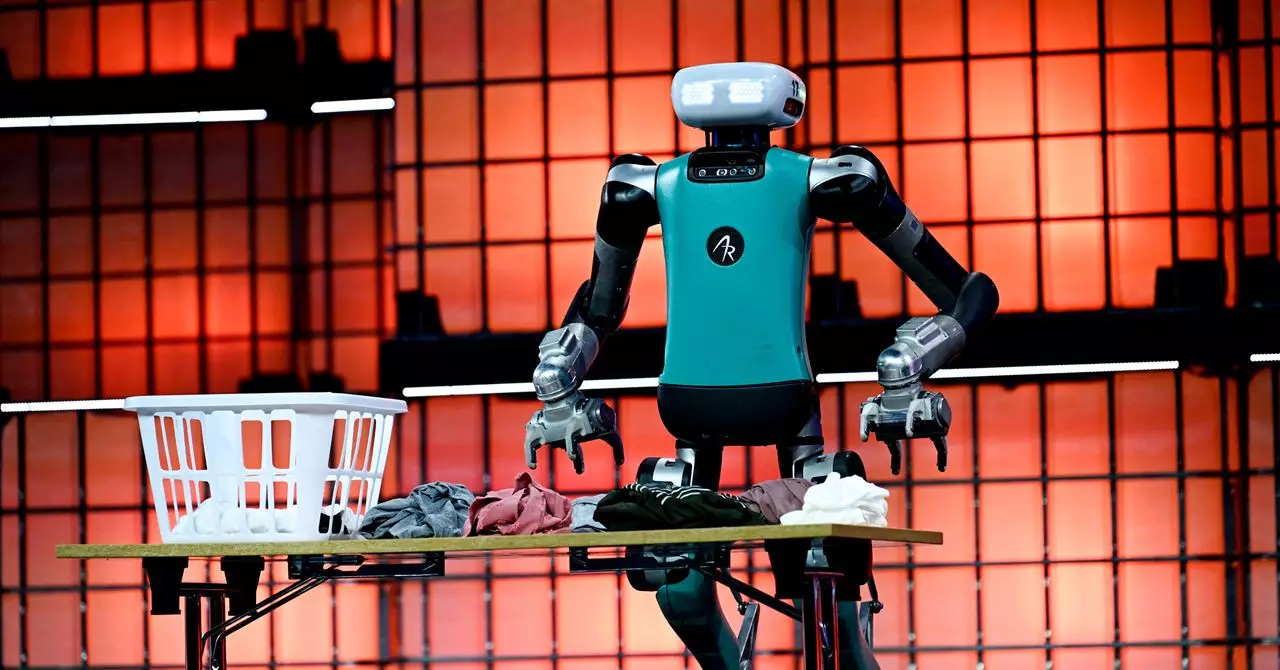

The Commercial Robot Revolution

The anticipation surrounding humanoid robots is palpable across industries. By 2025, we could see a surge of humanoid robots breaking free from the confines of research and entering the commercial realm. Organizations like Agility Robotics and Figure are already pioneering moves into practical applications, and tech giants such as Apple and Meta seem to be trailing closely behind, hinting at ambitious projects in humanoid robotics. This widespread interest hints at a burgeoning market, with projections from Goldman Sachs estimating that humanoid robots could represent a staggering $38 billion industry by 2035—a figure that dwarfs previous estimates and reflects a growing recognition of their potential.

Transforming Traditional Manufacturing

The introduction of robots like Atlas is set to revolutionize traditional manufacturing paradigms. The robotic integration stands in stark contrast to conventional assembly line automation, which has historically focused on tailoring entire production environments for specific tasks. Jonathan Hurst, co-founder of Agility Robotics, asserts that rather than disrupt existing workflows, humanoid robots can coexist within these settings, providing flexibility that rigid automation cannot match. This adaptability is particularly crucial for roles that do not require constant attention, allowing for opportunities to streamline operations with intelligent robotic assistance.

Challenges Ahead

Despite the promising landscape, there are hurdles to overcome before humanoid robots can become a ubiquitous presence in workplaces. Take for instance Tesla’s Optimus robot, which has been marred by skepticism following demonstrations that revealed the robots required human direction to perform tasks. Such instances cast doubt on the autonomous capabilities of these machines and highlight the challenges of public perception and technological evolution. Elon Musk’s oscillating comments regarding Tesla’s production capacity also reflect the intricate web of factors influencing the advancement of humanoid robotics, including geopolitical tensions affecting resources crucial for manufacturing.

The Human-Centric Future of Robotics

Boston Dynamics champions a vision where robots operate within a human-centric framework. Kerri Neelon emphasized the need for robots like Atlas to navigate environments built for human safety and efficiency. By striving for a symbiotic relationship between humans and robots, companies can create safer workplaces that harness the strengths of both entities. With factories already established as foundational safety zones for automation, there lies enormous potential in extending robotic capabilities beyond simple tasks to more complex, variable functions.

The evolution of humanoid robots in manufacturing is not just a technological upgrade; it’s a paradigm shift. As we witness this transformation unfold, the real question remains: how will we integrate these machines into our daily work lives, creating a future where humans and robots no longer compete, but collaborate in ways we have only begun to imagine?

Leave a Reply