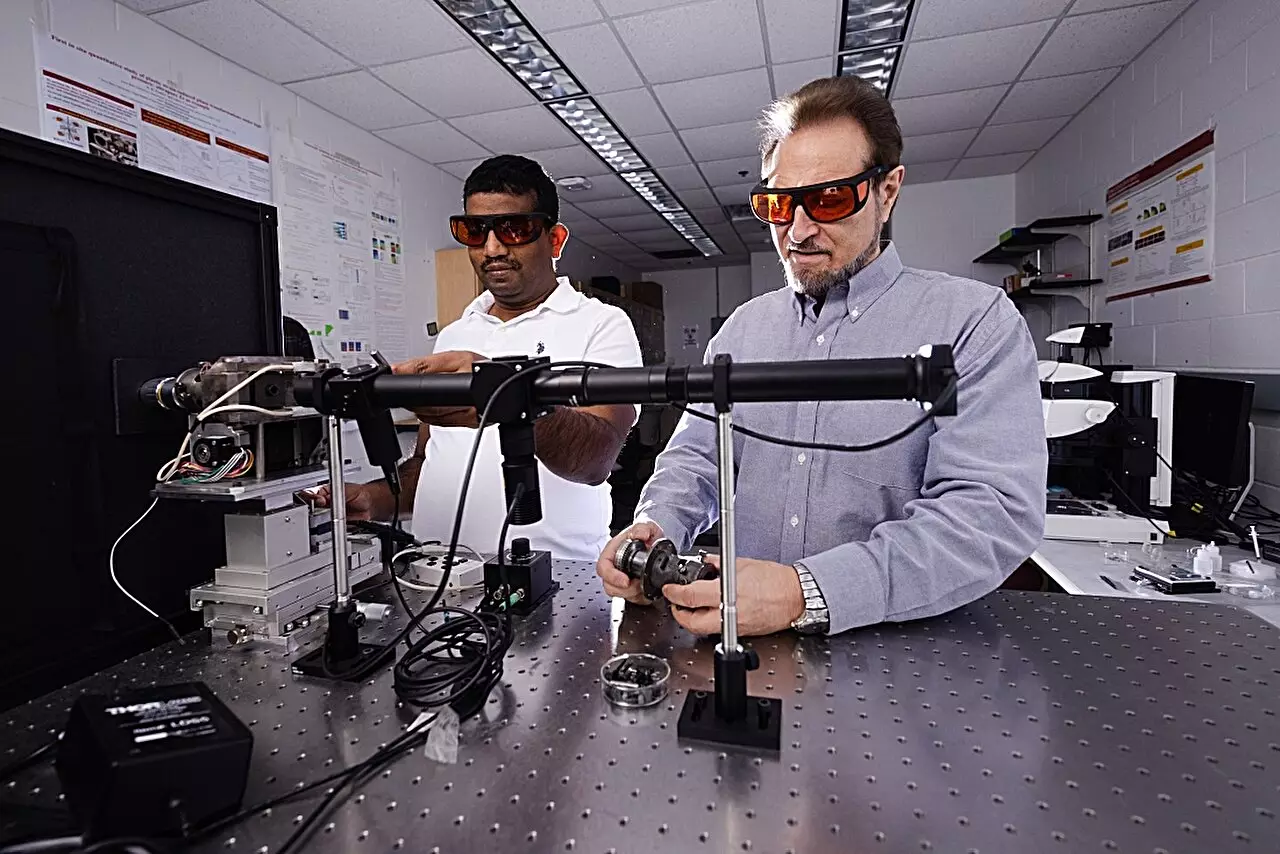

In 1999, Valery Levitas took a pioneering step in the realm of material science by moving from Europe to the United States with a rotational diamond anvil cell in tow. This sophisticated instrument has since undergone significant advancements, now serving as a critical tool for researchers exploring the effects of high pressure and shear on various materials. Levitas and his team delve into an interdisciplinary approach that merges mechanics, physics, material science, and applied mathematics to push the boundaries of our understanding of material transformations. This research is particularly impactful, focusing on how crystal structures evolve under stress, yielding insights into new, potentially valuable material properties.

The ongoing studies reveal how materials can undergo distinctive changes when subjected to unique experimental conditions, including varying levels of pressure and deformation. The most recent findings shed light on silicon, a cornerstone material in electronics, which becomes particularly interesting when exposed to these experimental strains. Published in the journal Nature Communications, the work underscores silicon’s unexpected phase transitions under pressure and plastic deformation, challenging established notions within the scientific community.

The recent experiments led by Levitas, along with key collaborators, have unveiled unusual phase transformations in silicon when applied to various particle sizes and subjected to the pressures created by the diamond anvil cell. This cutting-edge study meticulously analyzed three sizes of silicon particles—measuring one millionth, thirty billionths, and one hundred billionths of a meter. Notably, the research fills a significant gap in the existing literature on silicon, which has primarily focused on pressure-induced transformations, overlooking the combined effects of pressure and plastic shear deformation.

In distinct contrast to previous studies, the researchers observed that at pressures as low as 0.3 gigapascals, silicon could transition from the “Si-I” crystal phase to the “Si-II” phase—an impressive drop from the typical pressure threshold of 16.2 gigapascals required for such phase transformations. This remarkable finding establishes a newfound understanding of material behavior under applied stress. Levitas points out that this addresses a crucial aspect of material science: the aspiration to reduce transformation pressures, which has implications for practical applications far beyond theoretical inquiry.

The implications of this research extend significantly into industrial practice. As Levitas articulates, the traditional high-pressure methods for inducing phase transformations are often impractical for commercial applications. The novel approach of utilizing plastic deformation opens the door to accessing high-pressure phase properties without the burdensome constraints of extreme pressure environments. The versatility of this technique could lead to innovative manufacturing methods that harness the desired nanostructured phases of silicon or silicon-based nanocomposites, offering enhanced electronic, optical, and mechanical properties.

Moreover, by fundamentally altering the microstructure rather than the physical shape or size of the material, the researchers have laid the groundwork for optimizing the unique characteristics of silicon. Employing this methodology, industry could potentially embrace significant advancements across various applications, from semiconductors to advanced material composites.

Levitas emphasizes the importance of a hypothesis-driven approach; his team’s expectation of silicon’s unusual reactions to strain led them to explore low-pressure transformations actively. This reconceptualization of material conditions within experimentation not only upholds the integrity of theoretical frameworks but also encourages innovative exploration beyond conventional research paradigms. Such foresight could lead to groundbreaking discoveries in material science and engineering.

The transformative research conducted by Levitas and his colleagues serves as a crucial intersection of theory and practical application. Their findings not only challenge established theories surrounding silicon but also redefine the methodologies and pressures associated with high-performance materials. It is this spirit of inquiry and experimentation that will continue to propel the field of material science into uncharted territories.

Leave a Reply