In recent years, the construction industry has witnessed a surge in the utilization of Ultra-High-Performance Concrete (UHPC) due to its remarkable strength and durability. This unique structural material has established itself as a critical component in modern engineering projects, particularly in structures demanding heightened stability and longevity. However, engineers have faced significant challenges in understanding and predicting the behavior of UHPC, especially when reinforced with fiber-reinforced polymers (FRP). A groundbreaking study conducted by Zhang et al. has laid the groundwork for understanding this behavior more comprehensively, ushering in a new era of concrete science and engineering methodologies.

Traditional stress-strain models effectively describe the behaviors of normal-strength concrete (NSC) confined with FRP. However, these models have proven inadequate for UHPC, whose properties diverge significantly from those of NSC. The nuance lies in the failure mechanisms that occur under concentric compression, which are markedly different for UHPC. The study from Huazhong University of Science and Technology and Southern University of Science and Technology identified these gaps, prompting researchers to delve deeper into the compression responses of UHPC when enhanced with FRP.

Through a series of comprehensive experimental trials, the research team was able to expose key discrepancies between existing models and the actual behavior of FRP-confined UHPC. A significant conclusion drawn from their work was the revelation that assumptions based on stress-path independence—a theory applicable to NSC—does not hold true for UHPC. This finding necessitated a shift in perspective for engineers and researchers alike, highlighting the urgent need for innovative modeling techniques.

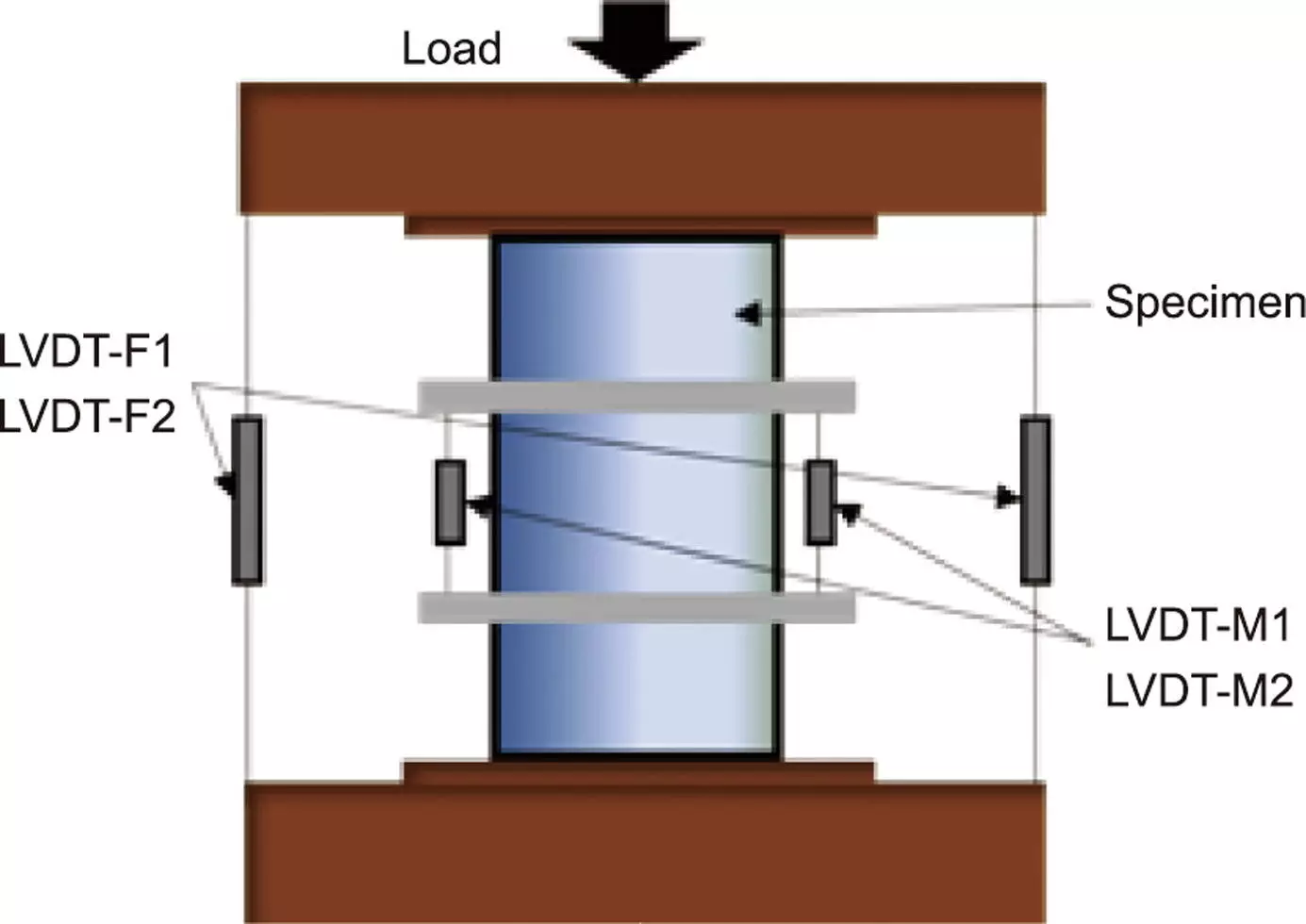

One of the notable insights produced by the research was the unexpected formation of major diagonal cracks in FRP-confined UHPC. This phenomenon triggered non-uniform lateral expansion, resulting in a decrease of effective confining pressure transferred from the FRP to the UHPC. The complexity of this interaction challenged the established paradigms and reinforced the need for a more accurate methodological approach.

To accommodate the distinct features of UHPC under load, the researchers curated a new analytical model that integrates stress-path dependency—a factor that had previously been overlooked. By refining the equations related to confining pressure and establishing a relationship to account for the confining pressure gap, they laid the groundwork for a more precise tool to predict UHPC behavior.

The new model underwent rigorous validation against a comprehensive database of experimental results. This extensive process demonstrated that the revised model could more accurately predict the stress-strain behavior of FRP-confined UHPC compared to previous frameworks that failed to incorporate the unique characteristics of UHPC.

The implications of this advancement are profound. Engineers can now rely on this newfound knowledge to design UHPC structures with enhanced safety features, optimized performance, and extended durability. The refined model not only strengthens the structural integrity of buildings but may also lead to more sustainable construction practices through more innovative and efficient design strategies.

As the study sheds light on the complex behaviors associated with UHPC, it serves as a catalyst for future research within the field. The acknowledgment of stress-path dependency opens new avenues for exploration, encouraging further innovations in concrete technology. With the construction industry relentlessly evolving, the insights garnered from this research could be instrumental in tackling future engineering challenges.

The advancement in analyzing the behavior of FRP-confined UHPC marks a significant leap for structural engineering. The insights provided by Zhang and his colleagues empower engineers to push the boundaries of high-performance concrete applications. This study is not merely a scientific endeavor; it is a pivotal contribution that underscores the evolving symbiosis between material science and structural engineering, redefining how we approach construction design in an increasingly complex and demanding landscape.

Leave a Reply