In an era where environmental sustainability is no longer just a buzzword but a necessary paradigm, researchers are pivoting towards eco-friendly alternatives to traditional battery technology. A promising breakthrough has emerged from a collaborative effort between POSTECH and Hansol Chemical — a novel battery system utilizing a fluorine-free binder and electrolyte. This development, recently documented in the Chemical Engineering Journal, holds the potential to redefine the standards for high-performance batteries while adhering to the pressing demands of environmental regulations.

The Flaws of Conventional Lithium Batteries

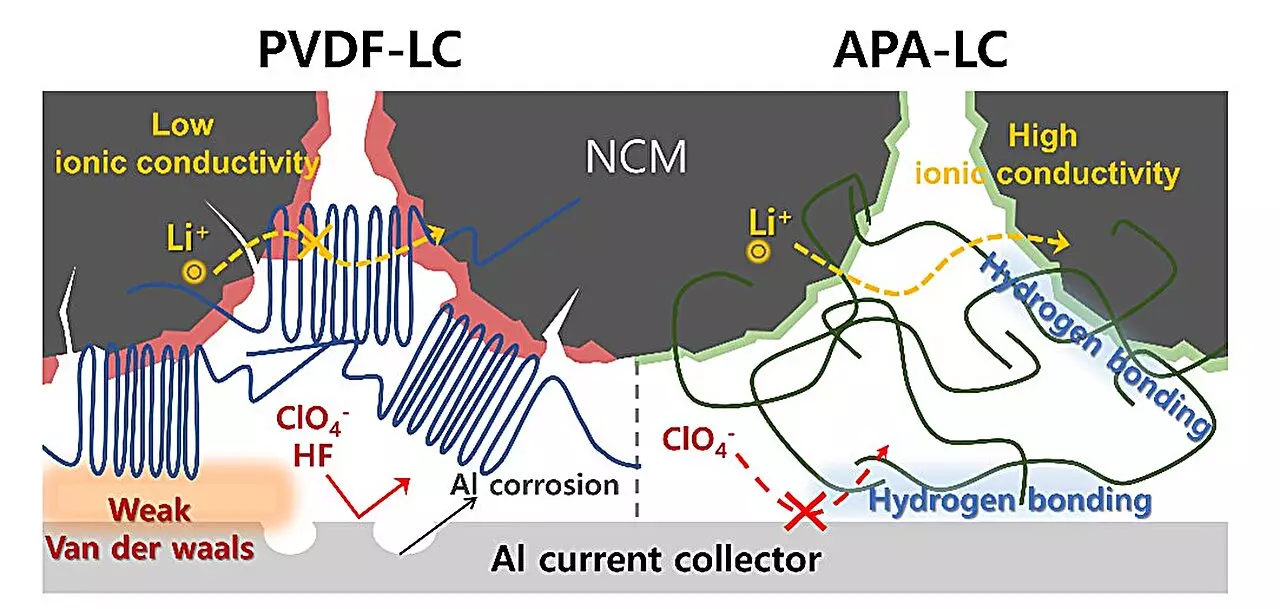

Traditional lithium-ion batteries frequently incorporate fluorinated compounds, such as polyvinylidene fluoride (PVDF) as binders and lithium hexafluorophosphate (LiPF6) salts as electrolytes. While these materials have garnered popularity due to their effectiveness, they come with significant drawbacks. Notably, the PVDF-LiPF6 combination contributes to the emission of hydrogen fluoride (HF), a highly toxic substance that not only imperils user safety but also compromises the longevity and efficiency of battery systems. Furthermore, the non-biodegradable nature of PVDF poses environmental hazards, particularly as legislative measures, especially in the European Union, move towards stringent regulations against per- and polyfluoroalkyl substances (PFAS). As a result, battery developers are faced with a dilemma: how to innovate within an industry constrained by growing ecological concerns.

A Breakthrough in Non-Fluorinated Technology

Responding to these urgent challenges, the research team has devised a fluorine-free alternative dubbed the “APA-LC” system. This innovation integrates a lithium perchlorate (LiClO4)-based electrolyte in place of the toxic fluorinated counterparts, alongside a non-fluorinated aromatic polyamide (APA) binder. The APA binder is not merely a replacement; it enhances the cohesion of the cathode’s active materials with the aluminum current collector, thus mitigating the risk of electrode corrosion within the electrolyte. This ingenuity does not just meet emerging regulatory standards — it also promises enhanced battery life through effective performance.

Moreover, the inclusion of lithium chloride and lithium oxide in the LC system significantly reduces the energy barrier at the interface for ion migration. This additional feature accelerates lithium diffusion, excitingly indicating superior output performance relative to traditional systems. Experimental trials demonstrate the efficacy of the APA-LC system; it exhibits remarkable oxidation stability, achieving a 20% boost in capacity retention after 200 cycles, even under rapid charge/discharge conditions.

The research team hasn’t simply theorized about the APA-LC’s advantages; they have also put it through rigorous testing. By manufacturing a high-capacity 1.5 Ah pouch cell utilizing their innovative system, researchers recorded exceptional discharge capacity and performance stability during fast-charging tests. This is particularly notable as it represents the world’s inaugural demonstration of a reliable battery system free of fluorinated materials, effectively merging practical usability with environmental compliance.

Professor Soojin Park, who led the research at POSTECH, articulates the significance of their success succinctly: “We’ve not only replaced fluorinated components; we’ve established a benchmark for capacity retention and stability that aligns with the sustainability goals of the battery industry.” This profound statement underscores the ambition driving this team — an ambition to transform the landscape of battery production for future generations.

As the implications of this breakthrough extend beyond laboratory achievements, industry players are taking note. Young-Ho Yoon, the Managing Director of Hansol Chemical’s Secondary Battery Materials Business, emphasizes the strategic advantages of this innovation. With PFAS regulations shaping the future of the battery materials market, he notes that this development positions Hansol as a frontrunner in what is projected to be a KRW 1.7 trillion global industry by 2026.

Continued research and refinement of the APA-LC system could solidify its position in the marketplace, promising to enrich the landscape of eco-friendly battery materials. As industries worldwide grapple with the demand for sustainable solutions, this research may represent a pivotal shift toward environmentally responsible technology that safeguards both performance and the planet.

The journey towards sustainable battery technology, exemplified by the new APA-LC system, illustrates a critical intersection of innovation and ecological responsibility. As researchers and industries collaborate, the future of battery technology appears not only promising but essential for steering towards a greener, more sustainable planet. With continued exploration and commitment to eco-friendly practices, the dream of harnessing energy in a manner that respects environmental boundaries becomes increasingly attainable.

Leave a Reply