The intersection of artificial intelligence and materials science is unveiling groundbreaking possibilities in multiple fields, notably nuclear fusion. A pioneering study from the Oak Ridge National Laboratory (ORNL) showcases how AI can drastically improve the process of identifying new alloys specifically designed for use in fusion reactors. This development is particularly significant as the quest for effective and efficient materials is central to the realization of practical nuclear fusion energy.

The quest for advanced materials that can withstand extreme conditions in nuclear fusion environments has been ongoing. Traditional approaches have relied heavily on tungsten-based alloys, which, while effective at high temperatures, often fall short in maintaining consistent shielding properties—a requirement critical for ensuring the safe operation of fusion reactors. Recognizing these limitations, the ORNL team embarked on a journey to explore novel materials under the leadership of AI initiative director David Womble. The hope was to transcend the outdated methodologies that hampered scientific progress.

Massimiliano Lupo Pasini, an AI data scientist at ORNL, played a pivotal role in steering the project towards utilizing AI to streamline the alloy identification process. The sheer number of potential metallic combinations presents a significant challenge, making traditional methods reliant on trial-and-error impractical and time-consuming. Through the study, the researchers leveraged AI capabilities to sift through vast data, allowing them to focus on promising candidates without being bogged down by the exhaustive trials that historically characterized materials science research.

This strategic shift is essential, especially in an era marked by a pushing need for a clean and sustainable energy source derived from nuclear fusion. By employing AI in this context, researchers can understand complex material interactions at various temperatures and mechanical properties, laying the groundwork for future breakthroughs.

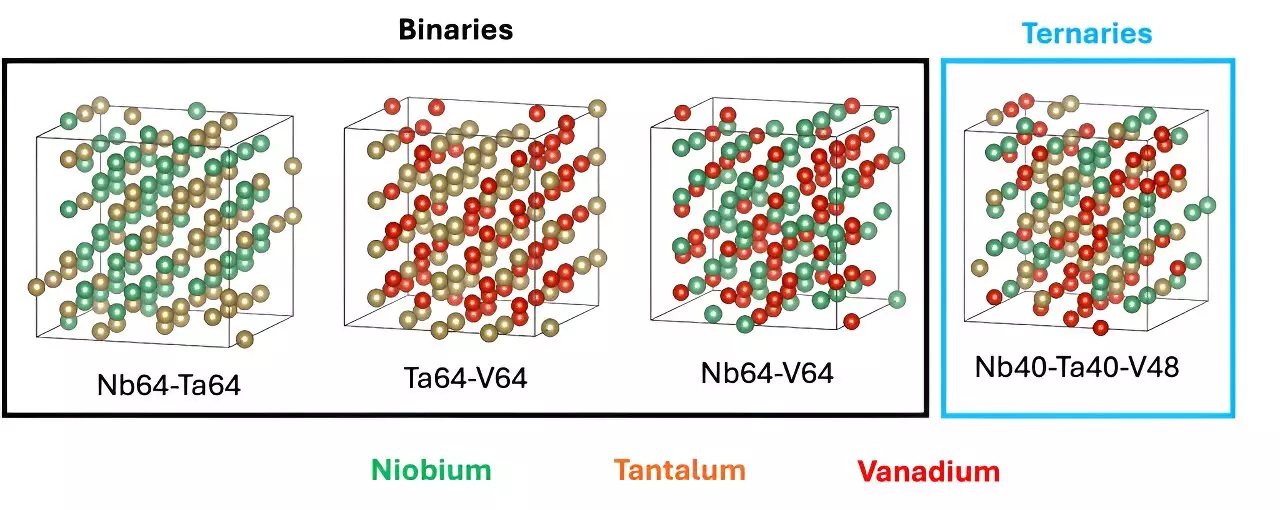

A multi-disciplinary collaboration was central to the research’s success, involving experts such as German Samolyuk, Jong Youl Choi, Markus Eisenbach, Junqi Yin, and Ying Yang from various directorates within ORNL. They collaborated to generate a robust AI model capable of identifying potential alloy candidates by manipulating the parameters of alloy compositions. The AI model identified three elements worthy of further investigation, potentially paving the way for new alloys with superior performance in fusion applications.

The process of creating and training the AI model was rigorous, involving extensive computational resources. The use of high-performance supercomputers like Perlmutter and Summit underscores the techno-scientific investments necessary to complete such complex modeling efforts. Generating the relevant data for this AI model consumed a significant amount of time and resources, taking over a year to reach completion.

Despite the successful creation of an AI-generated database, challenges remain. Lupo Pasini pointed out that to fully realize the potential of developed alloys, the scientific community needs to integrate six different elements, which compounds the complexity of the project. Furthermore, quantum mechanical calculations—crucial for validating and characterizing the properties of these new alloys—are resource-intensive and require robust computational capabilities. The researchers recognized that data alone wouldn’t suffice; it must be combined with advanced modeling techniques to facilitate the design of new alloys.

The acknowledged high costs associated with quantum-level simulations present a daunting barrier. However, the collaboration continues to strategize on how to leverage their existing data to refine their AI models further, aiming to streamline the alloy discovery process.

Looking forward, the ORNL research team is set on transforming how materials are discovered and designed, aspiring to alleviate the burdens facing material scientists. The AI model aims to provide enhanced guidance in determining the optimal mixtures of different elements to create alloys that can not only improve current technologies but lead to revolutionary advancements in fusion technology.

The revelations emerging from ORNL’s recent study illustrate a promising future for AI in materials science. By marrying modern computational methodologies with traditional scientific inquiry, researchers are poised to embark on a transformative journey for nuclear fusion technology, potentially unlocking new pathways to clean and sustainable energy. The implications of this research extend beyond nuclear fusion, setting a precedent for AI’s role in various materials development endeavors across various scientific domains.

Leave a Reply