As we navigate through life’s obstacles, we tend to gravitate towards intricate solutions to complex problems. However, the key to finding resolutions often lies in simplifying the core essence of the issue. This notion was exemplified by a recent study conducted by a research team at Pohang University of Science and Technology (POSTECH), where they tackled the challenges associated with solid-state batteries.

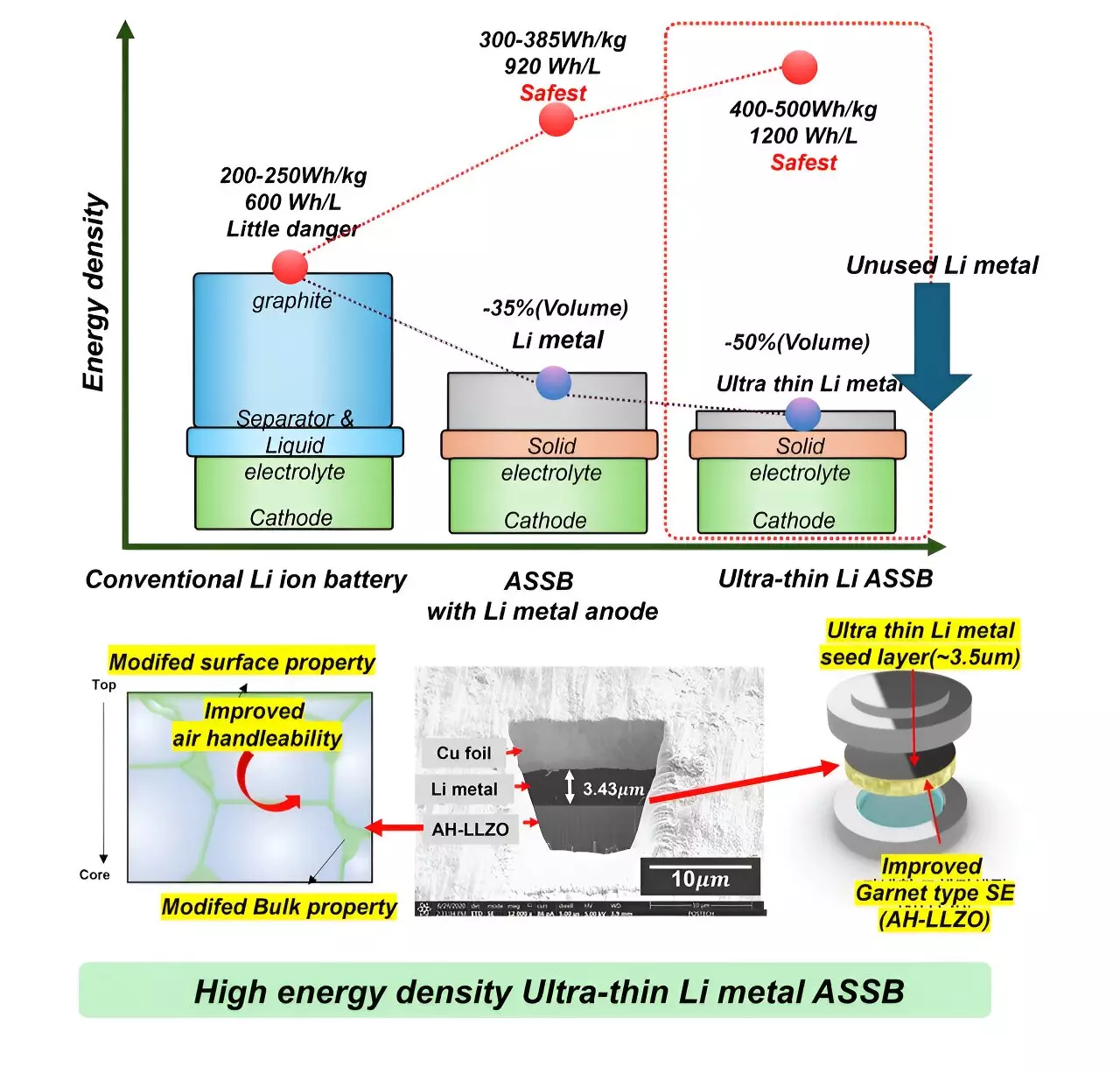

Solid-state batteries, heralded as the next generation of batteries due to their enhanced energy density and safety features, utilize solid electrolytes in place of liquid ones. Among the various types of solid electrolytes, the garnet-type oxide solid electrolyte (Li7La3Zr2O12 or LLZO) stands out for its high ionic conductivity. However, LLZO is prone to reacting with the air, forming a contamination layer (Li2CO3) on its surface. This layer poses a hindrance in cell construction, affecting the performance of the electrolyte and reactants, particularly the lithium (Li) metal anode.

Rather than resorting to conventional methods of coating the LLZO surface or employing additional chemical treatments post-synthesis, the research team at POSTECH took a different approach. They focused on enhancing the LLZO itself to tackle the issue at its core, without the need for external interventions. By simplifying the process and concentrating on the essentials, they developed an innovative technology known as air-handleable LLZO (AH-LLZO).

The AH-LLZO technology introduced by the research team at POSTECH aimed to improve the surface and internal properties of LLZO, thereby preventing the formation of contaminant layers. Through a series of experiments, they were able to inhibit the creation of the contamination layer by generating a new hydrophobic compound (Li-Al-O) on both the surface and inside the material. This breakthrough not only enhanced the contact and wettability with lithium metal but also allowed for the production of ultra-thin lithium solid-state batteries.

The development of ultra-thin lithium solid-state batteries, with a thickness of approximately 3.43 μm, signifies a major advancement in battery technology. This innovation drastically reduces the amount of lithium metal required, leading to a lower overall battery weight and volume, while significantly improving energy density. Moreover, the technology enables the storage of garnet-type solid electrolytes in air without the need for specialized handling or facilities, streamlining the process and making it more practical for everyday use.

The research conducted by the team at POSTECH showcases the power of simplification in addressing complex challenges. By focusing on the core essence of the issue and developing a novel solution, they have revolutionized the field of solid-state batteries. This study serves as a reminder that sometimes, the most effective answers are found by stripping away the complexities and honing in on the fundamentals.

Leave a Reply